intro to 3d printing

class description

3d printing students work collaboratively with students from the electronics, programming, invention and design classes to prototype and produce innovative new devices and products. In addition to becoming fluent in additive design and printing, students will master engineering principles, problem-solving methodologies, and collaborative work skills. Students will not only leave with tangible printed objects as with many 3d printing classes, but will have performed a key role in designing and producing new, complex devices, with skills that will be highly valued across multiple industries and fields.

course curriculum

introduction

Students will receive a comprehensive introduction to the additive manufacturing process, a comparison of various 3d printing technologies, and an understanding of where and when each would best be applied. We will explore the range of materials used in 3d printing, and learn to select ideal materials for different tasks and project requirements.

We will discuss how and when 3d printing can be advantageously applied in current, real-world prototyping and manufacturing scenarios. We will likewise discuss the many advantages and disadvantages of choosing 3d printing over other prototyping and manufacturing methods.

For a broader perspective, we will explore the societal impact of 3d printing, emerging trends in 3d printing technology, and where 3d printing is likely to make the largest impacts in the near future. We will introduce potential career paths in 3d printing fields like design engineering, materials science, software development for CAD tools, quality control, and research.

modeling fundamentals

The class will dive into form modeling in Autodesk TinkerCAD and later, Autodesk Fusion. Even as we begin with basic shapes, elements and tools, we will be applying and adhereing to a consistent organizational framework, with processes, policies, standards and techniques meant to serve as a foundation for more advanced and challenging projects.

slicing software and file preparation

The class will next focus on the key role of slicing software in preparing 3d models for printing. We will learn how slicing converts a 3d model into layers for printing, and how it determines the tool path for optimal print quality and efficiency. We will explore G-code, the instruction language of 3d printers, and the slicing algorithms that break down a 3d model into segments for printing. We will learn to optimize our projects in Ultimaker's popular Cura software, for the most successful printer output. We will investigate the array of advanced software settings in a systematic manner to clarify their impact on print quality, while learning to balance factors like speed, quality, and material usage for efficient printing.In the process, we will develop troubleshooting skills by analyzing G-code, understanding slicing errors, and learning how to address common issues during the printing process.

equipment use and calibration

A key factor to print success is proper setup and maintenance of the printer itself. Students will shift focus to the proper use of sensitive measuring tools for adjusting and leveling the various gantry and bed components. We will delve into methods for achieving consistent bed adhesion, and spend significant time on extruder calibration, flow rate adjustment, temperature control, and filament retraction optimization, since this is truly where the 'rubber meets the road.'

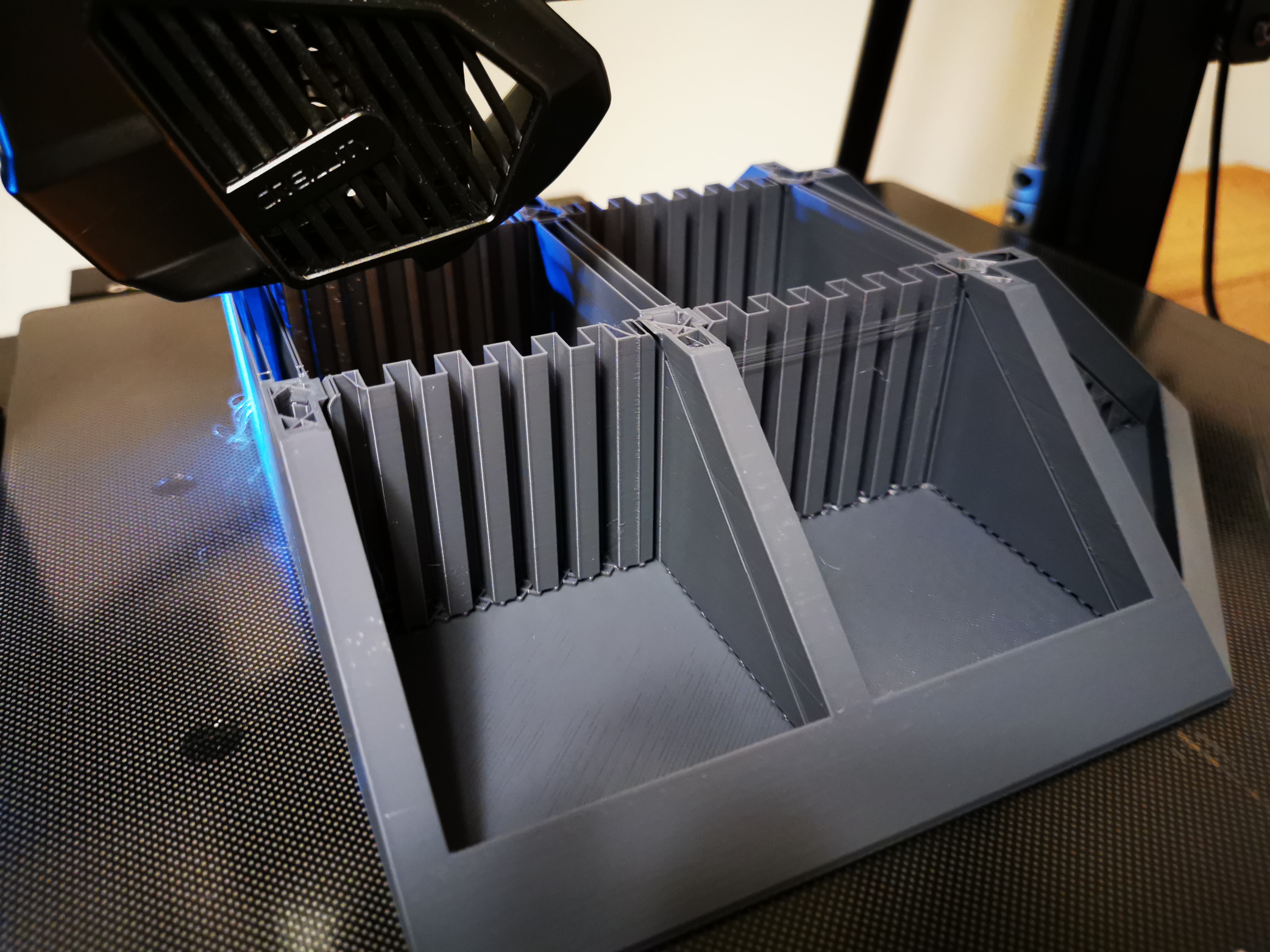

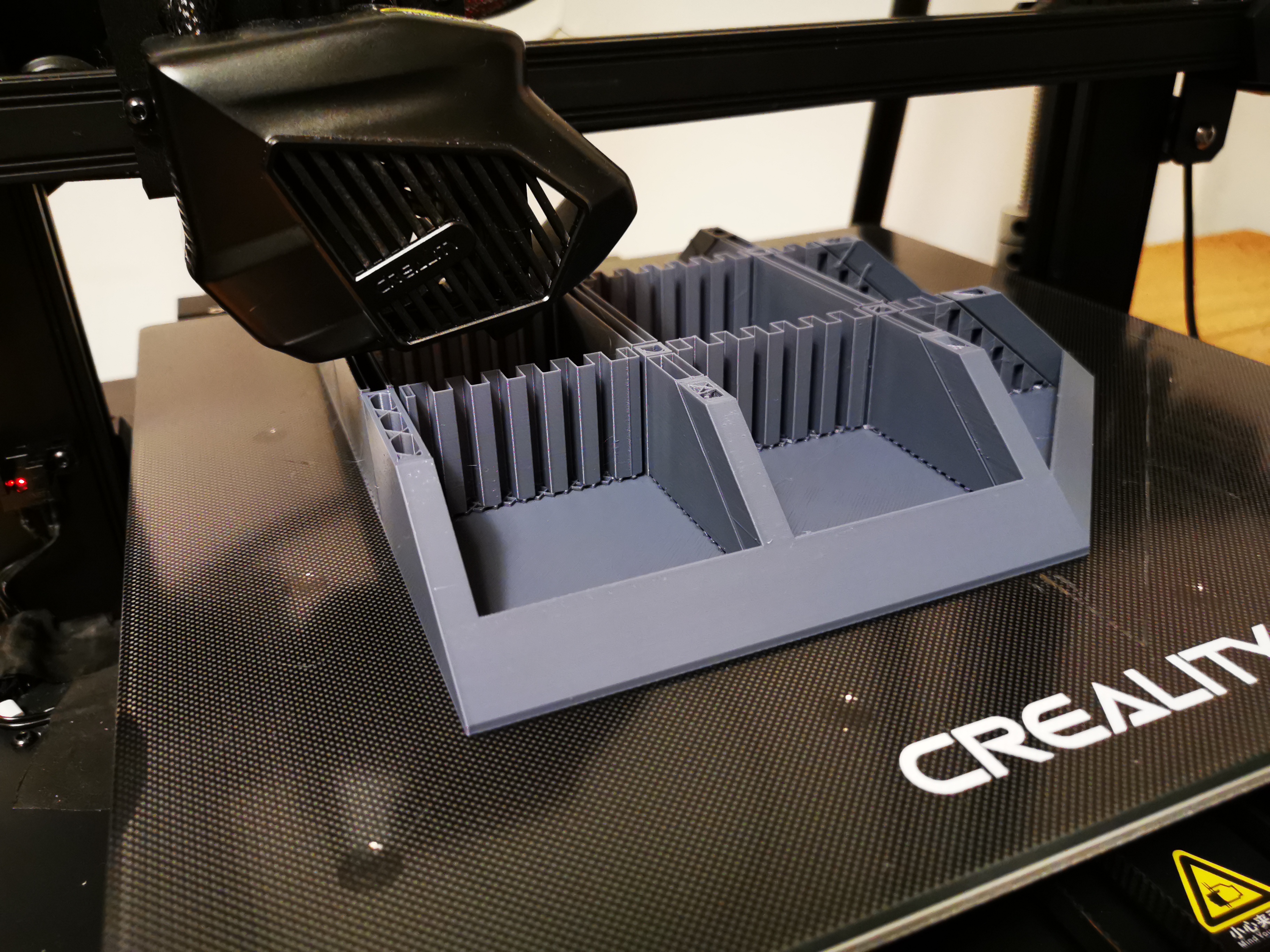

advanced component fabrication

Armed with strong 3d printing fundamentals, students will begin to work as teams to design and produce parts and components that successfully serve their intended purposes in larger product engineering projects. This iterative improvement process is structured to encourage a resilience mindset. We will delve deeply into the part testing and improvement loop by analyzing functionality, durability and similar issues, troubleshooting errors, and refining designs to achieve desired outcomes. We will explore post-processing techniques, like annealing and heat treatment, to enhance strength and durability characteristics.

aesthetic design, usability and finishing

We will conclude the course with a focus on aesthetic design, to produce parts and products that are not only functional, but graceful, accessible and market-ready. We will explore finishing techniques, from sanding and polishing to use of vapor smoothing and water-soluble support materials to produce the most professional outcomes possible in a learning environment.

a sampling of our planned projects:

- model rocket components

- customized enclosures for printed circuit boards

intro to 3d printing

class code

3dp01-sum25-01

classes in session

10

start date

6/24/2025

start time

3:45 pm

ages

12 - 15 (at class start date)

remaining available seats

10 of 10 seats

fee

$111.00

prerequisites

students must be comfortable working within their preferred computer operating system, and must be familiar with basic computer operations such as installing applications, naming and moving files, and troubleshooting basic issues with their machines.

required supplies

students must bring their own laptops, running up-to-date operating systems (either Apple OSX or Microsoft Windows, to all classes (we can not support Linux variants, nor ChromeOS in the classroom). students must have administrative rights to their laptops, so that they can install software as required by the class.